|

| |

Challenging a difficult process that requires high technology in another companiesWe have the advantage of processing special parts that require difficult techniques in comparison with other companies. To accumulate these know-how, we always challenge ourselves to difficult things. |

|

|

|

|

|

|

|

Precision parts used in automotive Variable nozzle for supercharged diesel and gasoline, compressor impeller

|

|

|

|

Perform mechanical processing from billet turbocharger rotors. Criterion about roughness of hole is 0.8s with unit micrometer. With the requirement criterion such as cylindrical, roundness, rectangular, R shape, ..make product type become more diverse.

・ Impeller / Mold CAST ・ ALL Cutting

| ・ VANE NOZZLE / Lost wax CAST ・ Mim CAST ・ Fine blanking | |

|

|

|

|

|

|

|

Precision mechanical components used in the medical devices.Metal components with precision shape to micron used in medical field

|

|

|

|

| |

|

|

The product is completed with the aviation in criterion with super accurate value from diverse materials such as Titanium, SUS316, SUS304, SUS303, SUS420, SUS416, A6061, C3604, SUM24L … Unit by the Micrometer is obvious. Because of very complicated shape, the point is how to satisfy the geometrical tolerance. This is possible through the fusion of machine maintenance and craftsmanship.

・ 0.2mm thin TITAN material processed parts

・ Stainless steel, aluminum, iron, tolerance parts of 4μm or less |  |

|

|

|

|

|

|

|

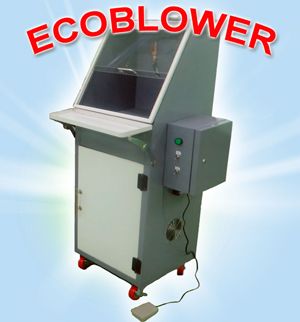

ECOBLOWER originally developed by TANOI!

Multi-functional device focusing on improving air blow work in the factory.

■ Dust collector integrated type: With a hood to prevent mist from scattering!

■ The work can be cooled with cooling air!

■ Workability is greatly improved with a foot switch!

■ Bright and comfortable with LED with motion sensor inside work hood!

■ Equipped with two types of injection nozzles, spot and wide-angle!

■ The amount of air used in the mechanical swing nozzle is 2/3 that of a general flat nozzle, and work efficiency is increased by 5 to 10 times!

■ It is possible to remove static electricity and dust from magnetic workpieces with ion air! |

|

|

Installation Effect

Before (with air-gun)

• Oil and Chips spread into the air, on the floor, and even clothes, making the whole workshop unclean as usual.

• 5S is hard to maintain in the oily factory.

• Waste productivity because of the stand-by time in work.

• Waste energy because air fun loads too much air on the air compressor.

After (with Ecoblower)

• Keep you and your workshop clean and neat.

• Keep it easy to maintain 5S.

• Make it better productivity without stand-by time.

• Save power energy to us air economically. |  |

|

|

|

|

|

|