|

| |

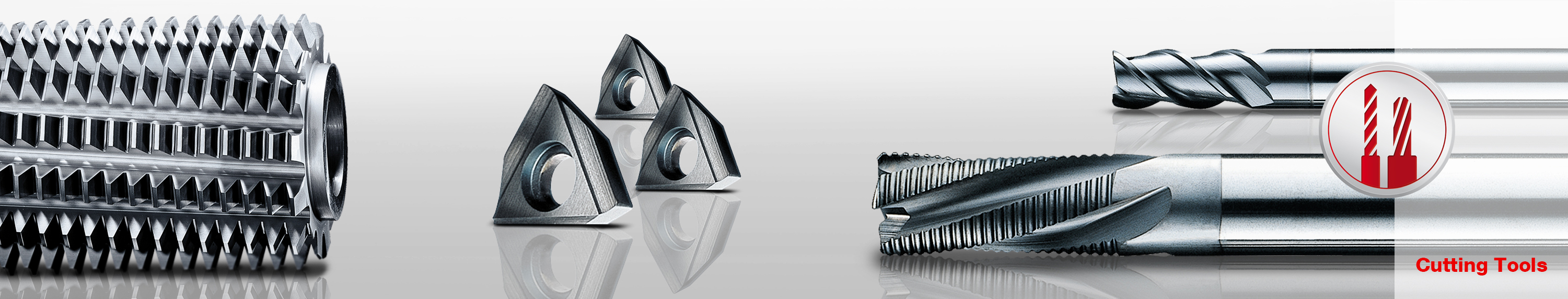

Coating Services for Cutting Tools

Your guide to higher machining productivity and cost efficiencyThe Oerlikon Balzers production process ensures high, reproducible quality all the time – worldwide:

- BALINIT® ALCRONA EVO (AlCrN) Gear & hard machining

- BALINIT® LATUMA (AlTiN) Mold & die

- BALINIT® TISAFLEX Diff cut mat: Ti, Inconel, SUS

- BALINIT® MAYURA for non-ferrous |

|

|

|

|

|

|

BALINIT ALCRONA EVO – the evolution of a coating legacy, pushing the boundaries of universal machining BALINIT ALCRONA EVO – the evolution of a coating legacy, pushing the boundaries of universal machining |

|

|

|

|

|

|

BALINIT® TISAFLEXMachining difficult-to-cut materials at the highest level

|

|

|

|

Titanium, nickel-based alloys, stainless steel and hardened steel push cutting tools to their performance limits. Consequently, industries in which these materials are increasingly being used – mould-making, aerospace, the 3C industry (computers, communications and consumer electronics) - are facing new challenges. Titanium, nickel-based alloys, stainless steel and hardened steel push cutting tools to their performance limits. Consequently, industries in which these materials are increasingly being used – mould-making, aerospace, the 3C industry (computers, communications and consumer electronics) - are facing new challenges.

BALINIT® TISAFLEX from Oerlikon Balzers provides outstanding oxidation resistance, high thermal stability and excellent wear resistance. The new high-end coating solution is thus the perfect solution for machining these demanding materials. |

|

|

|

|

|

|

BALINIT® MAYURAthe next generation of carbon-based coatings for machining non-ferrous materials

|

|

|

|

BALINIT® MAYURA catches the eye with its brilliant colours, and reveals its true value in the demanding machining and stamping of non-ferrous metals and polymers as well as in injection moulding. The carbon-based coating is harder and smoother than previous coatings, which minimises material adhesion, and it is extremely thin, which keeps cutting edges sharp. Tool manufacturers and end users benefit from increased tool life, maximum precision and higher productivity in the manufacturing process. BALINIT® MAYURA takes processing of non-ferrous materials to the next level. BALINIT® MAYURA catches the eye with its brilliant colours, and reveals its true value in the demanding machining and stamping of non-ferrous metals and polymers as well as in injection moulding. The carbon-based coating is harder and smoother than previous coatings, which minimises material adhesion, and it is extremely thin, which keeps cutting edges sharp. Tool manufacturers and end users benefit from increased tool life, maximum precision and higher productivity in the manufacturing process. BALINIT® MAYURA takes processing of non-ferrous materials to the next level. |

|

|

|

|

|

|

BALINIT® LATUMAHighest performance in cutting tools: milling, drilling and turning

|

|

|

|

Cutting tool manufacturing, mechanical engineering, aircraft industry and tool restoration companies have always wanted versatility and productivity. Cutting tool manufacturing, mechanical engineering, aircraft industry and tool restoration companies have always wanted versatility and productivity.

BALINIT® LATUMA offers decisive advantages - this coating is not merely machined and can be used on a wide range of materials, but efficiency and reliability are also increased at the same time throughout the machining process under harsh working conditions. Customers when using BALINIT® LATUMA coating with OERLIKON BALZERS’ leading surface hardening technology for inserts, metalworking tools in general will help the machining process to increase new heights and successes.

Outstanding features of this coating:

- For harsh machining conditions

- High resistance to abrasion and oxidation

- Ideal for both machining with and without coolant |

|

|

|

|

|

|

Regrinding + Recoating ServiceONE - STOP - PARTNER High quality and cost-effectiveness

|

|

|

|

In the past, tools were passed from one provider to the next during reconditioning. Oerlikon Balzers now offers a "one-stop-shop" service for round tools: an integrated service concept for your high-performance round tools with all reconditioning steps under one roof. Pickup and receipt of your tools, regrinding and recoating, packaging and delivery - we handle everything with single-source convenience, tailored to your needs. In the past, tools were passed from one provider to the next during reconditioning. Oerlikon Balzers now offers a "one-stop-shop" service for round tools: an integrated service concept for your high-performance round tools with all reconditioning steps under one roof. Pickup and receipt of your tools, regrinding and recoating, packaging and delivery - we handle everything with single-source convenience, tailored to your needs.

The result: round tools that are not just reconditioned and returned to you quickly, but also cost-effectively and with superior quality – with the coating portfolio of the world’s leading provider of job coating services and with as-new performance. This is why Oerlikon Balzers is your optimal partner for round tool reconditioning. |

|

|

|

|

|

|

|