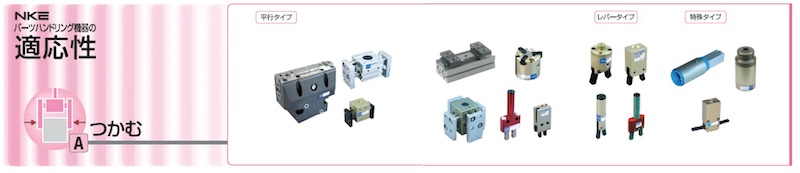

Parts handling equipment* Click the above image to enlarge the image |

|

|

|

|

|

|

≪Features≫ ≪Features≫

・ Parallel type small size

・ Ideal for handling small workpieces

・ Lightweight parallel chuck with large opening margin |

|

|

|

|

|

≪Features≫ ≪Features≫

・ Since the finger opens 180 degrees in a straight line, it can be moved laterally without retracting the chuck.

・ It is possible to attach a dust cover

・ The finger opening angle can be manufactured at any angle. |

|

|

|

|

|

≪Features≫ ≪Features≫

・ Parallel type square type

・ Can also be used in dust environments.

・ Compact chuck with large grip and stroke

・ There are finger orientations, vertical and horizontal. |

|

|

|

|

|

≪Features≫ ≪Features≫

・ The range of robot carrying restrictions will be expanded. The weight of the main body is halved, and heavy workpieces can be carried.

・ A larger number of pieces can be taken.

・ There is little blurring when stopped, and you can move smoothly. |

|

|

|

|

|

≪Features≫ ≪Features≫

・ Parallel / three-claw type

・ A chuck with a low overall height and a large opening allowance.

・ By supplying air from the scavenging port, foreign matter is prevented from entering the finger part.

・ Switches can be installed in up to 4 locations. |

|

|

|

|

|

≪Features≫ ≪Features≫

・ Parallel / square type

・ Easy positioning and transfer of round and square workpieces

・ Dustproof measures have been taken

・ Easy boxing of round workpieces

・ Only symmetrical nails are synchronized |

|

|

|

|

|

≪Features≫ ≪Features≫

・ Special type: Collet type

・ A handling collet chuck that is ideal for shaft workpieces.

・ The strong grip and the collet detent mechanism firmly grip the work.

・ Since there is a hollow hole, it can be used for long workpieces. |

|

|

|

|

|

≪Features≫ ≪Features≫

・ Special type ball claw type ・ Bottle chuck

・ Because it is gripped with a resin ball, the bottle will not be scratched.

・ Lightweight body that can be taken in large numbers

・ Customization is possible according to the features of the bottle. |

|

|

|