Product Introduction |

|

|

|

|

|

|

| Piston rings that control lubrication oil are an important functional component requiring high precision and durability since they are used in parts moving at great speed. |

|

|

Top ring with narrower width

【Features】

Shrinking ring width reduces piston weight and results in the improvement of fuel efficiency.

【Applications】

Gasoline engines for motor bikes, and small gasoline engines for automobiles |  |

|

Steel PVD top rings

【Features】

For current diesel rings, taking higher power output, durability, and anti-abrasion into consideration, materials are shifting from cast iron to steel, and surface treatment is shifting from nitride to PVD.

【Applications】Diesel engines for automobiles and others |  |

|

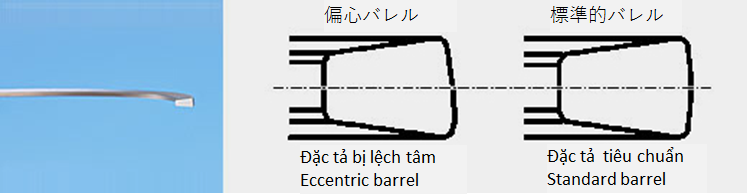

Eccentric barrel top rings

【Features】

For current diesel rings, the shape has been changing to be compatible for higher functions. Eccentric barrel rings aim to improve oil control functions by moving the peak position of the outer barrel of the ring that oscillates with the bore downward.

【Applications】Diesel engines for automobiles and others

|  |

|

Cast-iron piston ring

【Applications】

For gasoline

For diesel |  |

|

Race car piston rings

【Features】

Unfortunately, details of rings for motor sports cannot be displayed, however, we provide special rings that are optimum for engine characteristics.

【Applications】

Engines for domestic and overseas motor sports |  |

|

|

|

|

| With the recent demands for fuel efficiency, higher performance, and lighter weight engines, there is a growing trend for improving cooling performance, reducing clearance between cylinders, and using aluminum engine blocks. Consequently, TPR is striving to improve adherence to the aluminum block by applying centrifugal casting method to make liners thinner, and thereby achieve lower costs. |

|

|

Cast-in cylinder liner

【Features】

We can achieve low-cost through making As-cast spiny type. (Centrifugal casting method)It is superior in adhesion with aluminum by special As-cast spiny type.【Applications】

Various cars with aluminum engines |  |

|

|

|

|

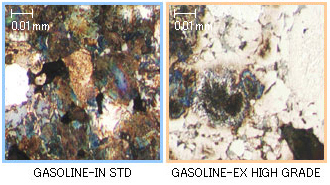

For materials used in production of sintered alloy valve seats, TPR breaks down particles using our proprietary special alloy powder. Featuring an excellent balance of heat resistance, wear-resistance, and compatibility with valves indispensable for valve seats, TPR provides sintered alloy products that are compatible with all engines, including diesel, gasoline, and gas for either two or four wheel vehicles. For materials used in production of sintered alloy valve seats, TPR breaks down particles using our proprietary special alloy powder. Featuring an excellent balance of heat resistance, wear-resistance, and compatibility with valves indispensable for valve seats, TPR provides sintered alloy products that are compatible with all engines, including diesel, gasoline, and gas for either two or four wheel vehicles. |

|

|

For gasoline engines

Intake valve seats must be inexpensive, strong, and easy to machine. TPR's valve seats are not only inexpensive but also able to be used in eco-friendly engines with high output and good fuel efficiency. |  |

|

|

|

|

Valve guides support the stem of inlet and exhaust valves, keeps valve stabilization and helps to conduct the heat of valve to the cylinder head, durability and high precision are needed. Our Sintered material valve guides are excellent in wear resistance, heat resistance and mechanical properties, adopted with number of gasoline engines and diesel engines. Valve guides support the stem of inlet and exhaust valves, keeps valve stabilization and helps to conduct the heat of valve to the cylinder head, durability and high precision are needed. Our Sintered material valve guides are excellent in wear resistance, heat resistance and mechanical properties, adopted with number of gasoline engines and diesel engines. |

|

|